Understanding High-Voltage Plugs and Global EV Charging Standards

The Role of High-Voltage Connectors in Electric Vehicles

The high voltage connectors ranging from 16A to 350A play a key role in transferring power efficiently between EV charging stations and vehicle batteries. When systems operate at voltages as high as 800 volts, we see significant reductions in energy loss during transmission, somewhere around 30 to maybe even 50 percent better than what lower voltage setups manage. This means vehicles can charge much quicker without overheating issues becoming problematic. Looking at real world applications, studies on these higher voltage systems indicate that reaching 350 kilowatts of charging power becomes possible with 800V architecture. That kind of speed matters a lot for businesses running large fleets where getting back on the road within twenty minutes or so makes all the difference operationally speaking.

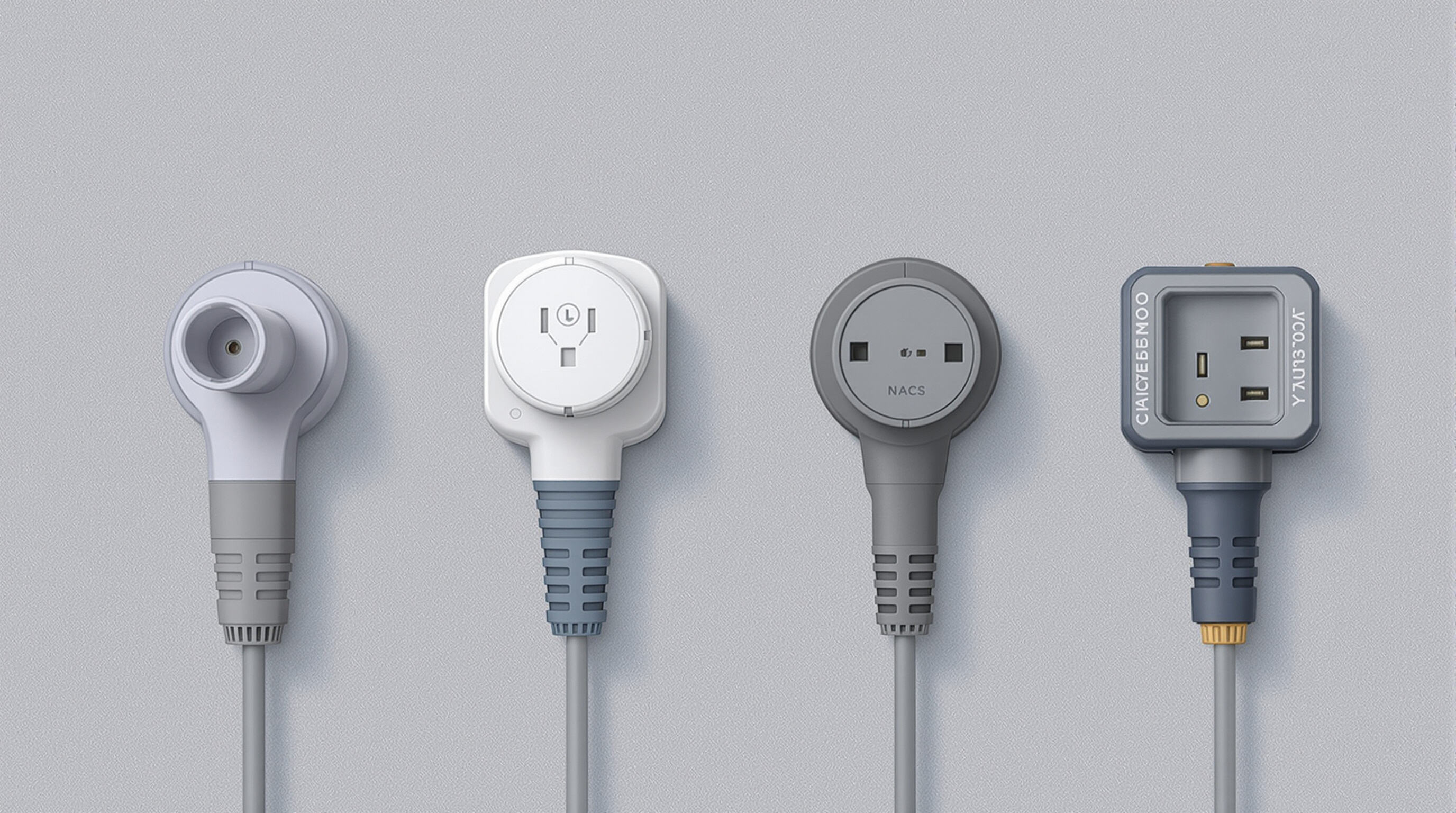

Comparative Analysis of Global DC Fast-Charging Plug Standards (CCS, CHAdeMO, GB/T, NACS)

Four plug types dominate DC fast-charging:

| Standard | Max Voltage | Peak Current | Regional Adoption |

|---|---|---|---|

| CCS | 1000V | 500A | North America/EU |

| CHAdeMO | 1000V | 400A | Japan |

| GB/T | 1500V | 600A | China |

| NACS | 1000V | 500A | North America |

A 2024 study in Energy Conversion and Management highlights CCS and NACS as the only standards natively supporting vehicle-to-grid (V2G) bidirectional charging.

Voltage and Current Specifications Across Different Charging Standards

Most connectors operate at 400V, 800V, with advanced chargers like Huawei’s 600 kW system pushing to 1500V. Current ratings directly impact charging speeds:

- 150A @ 400V = 60 kW (typical urban DC charger)

- 350A @ 800V = 280 kW (highway fast-charging)

- 500A @ 1000V = 500 kW (heavy-duty truck stations)

Higher currents require active liquid cooling in connectors—a feature now mandatory in SAE J3271-certified designs.

From AC to DC: How High-Power EV Charging Infrastructure Supports Up to 350 kW and Beyond

Switching from traditional AC charging (which maxes out around 22 kW) to DC fast charging allows electricity to go straight into the battery without going through those onboard converters first. Take a look at today's 350 kW stations they actually employ silicon carbide inverters now, which hit about 98.5% efficiency when operating at 800 volts. What does this mean? Drivers can get over 200 miles of driving range added back in just ten minutes of charging time. As these charging networks continue to grow, they're getting ready for the newer generation of 4C rate batteries on the market. At the same time, manufacturers are keeping things safe by sticking to ISO 6469-3 regulations regarding insulation resistance requirements above 1 gigohm and proper touch protection measures as well.

Electrical Performance of High-Voltage Plugs: Current, Power, and Efficiency

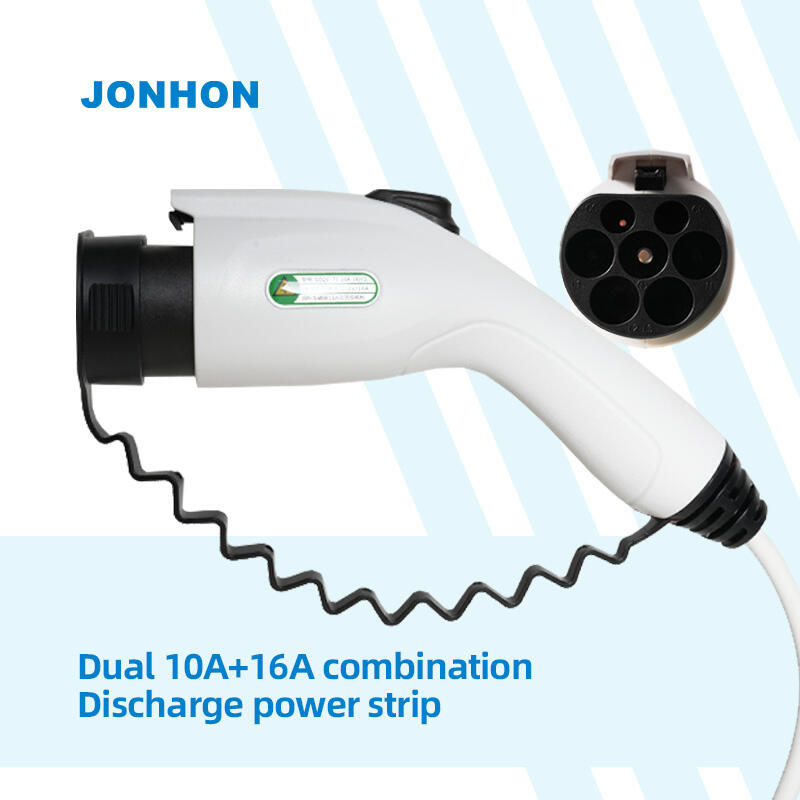

Current-Carrying Capacity of EV Connectors in the 16A, 350A Range

The high voltage plugs used in electric vehicles need to strike a delicate balance between handling enough current while staying safe from overheating. These connectors support everything from the modest 16 amp residential home chargers right up to those massive 350 amp commercial DC fast charging stations we see at service centers. The top companies in the business have figured out how to make these connections work better by machining their connectors from special copper alloys. This reduces resistance so they can actually handle those 350 amps without losing more than about 1.5% of the power along the way. What makes this whole system really useful is that it works across different types of electric cars too. Whether someone drives a small city car with a 40 kilowatt hour battery or needs something bigger like a long distance vehicle with 200 kilowatt hours, these connectors adapt to match what's needed.

Electrical Characteristics Including Voltage, Current, and Power Ratings

Today's electric vehicle connectors work within a voltage range of around 400 to 1,000 volts DC, which means they can deliver between 160 and 350 kilowatts when under maximum load conditions. Take for instance a connector rated at 350 amps operating at 800 volts - this setup produces approximately 280 kilowatts of power output. That kind of performance allows drivers to gain roughly 200 kilometers of driving range just by plugging in for 15 minutes. According to thermal analysis studies, the liquid cooled versions of these connectors stay operational without issues even when subjected to continuous 350 amp charging sessions. The components experience stress levels that remain comfortably under 5 percent throughout these demanding scenarios.

Charging Speed and Range per Hour Under Various Loads

| Load Scenario | Current (A) | Voltage (V) | Range Added/Hour |

|---|---|---|---|

| Urban Charging | 32A | 400V | 50, 65 km |

| Highway Fast | 200A | 800V | 300, 350 km |

| Ultra-Fast | 350A | 920V | 550, 600 km |

Connector Efficiency Benchmarks From SAE J1772 and IEC 62196 Standards

SAE J1772 in North America and IEC 62196 worldwide set minimum efficiency requirements at around 94% for electric vehicle connectors regardless of temperature conditions. Tests conducted recently indicate that top tier 350A connectors actually reach about 97% efficiency thanks to their multilayer silver plating and specially designed contact springs. This represents roughly a 6% improvement over older models on the market. The difference might seem small, but it translates into real savings too. During just half an hour of charging time, these improved connectors cut down wasted energy enough to power approximately twelve average sized homes for that period.

Design and Safety Features of High-Voltage Connectors in EV Applications

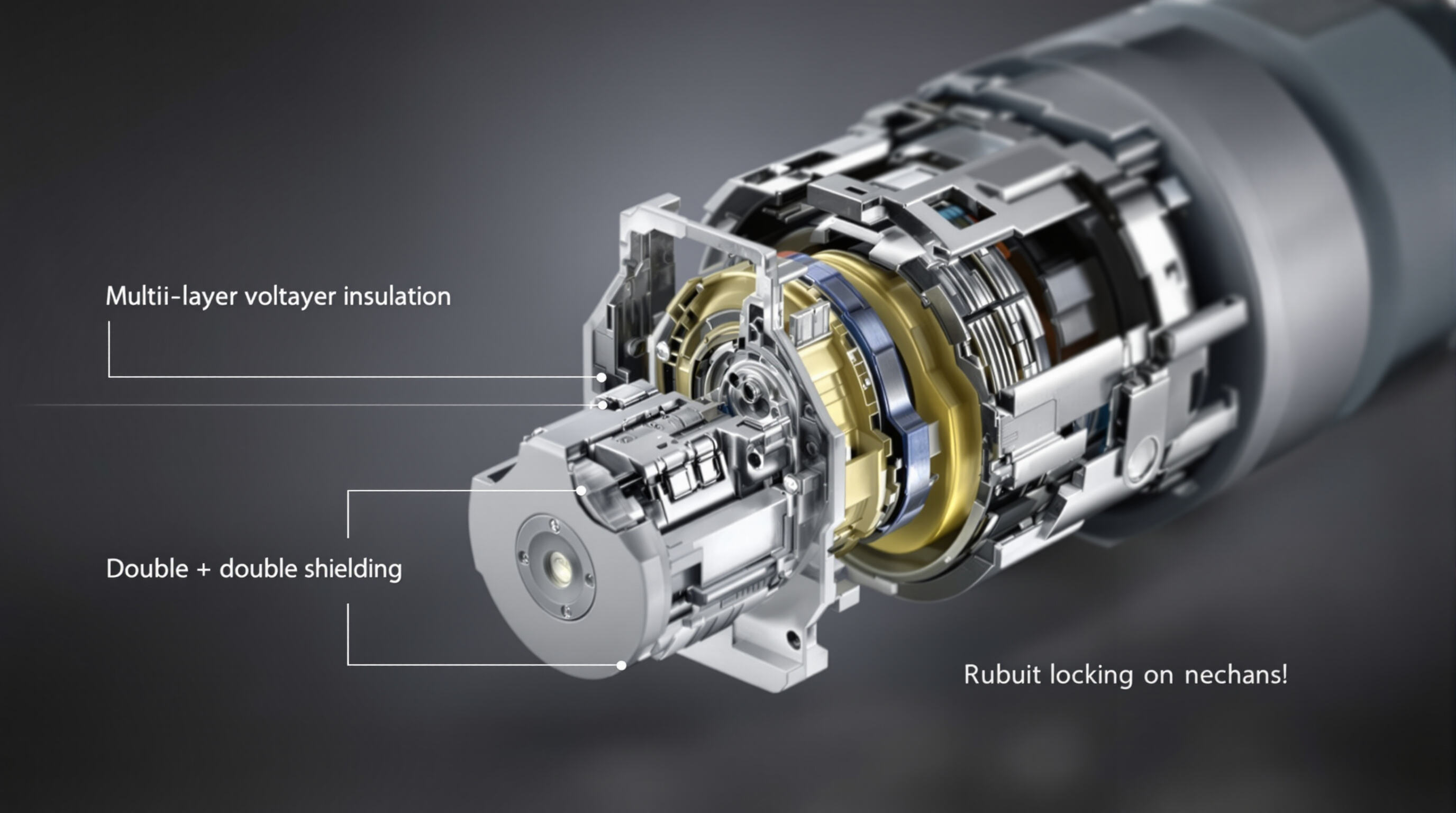

Insulation and shielding for fault prevention in high-voltage systems

High-voltage plugs employ multilayer insulation systems using materials like cross-linked polyethylene and fluorinated ethylene propylene to withstand over 1,000 volts. Double-shielded designs reduce electromagnetic interference by 72% compared to single-layer solutions. These systems prevent arc faults even at 350A loads, crucial for protecting EV battery management systems from catastrophic failures.

Latching and locking mechanisms for secure connections

MIL-STD-1344 compliant connectors use dual-stage latching with <20N engagement force and >200N retention strength. Spring-loaded secondary locks automatically engage when plugs seat completely, reducing connection errors by 41% in automotive validation testing. This meets IP67 and IP6K9K standards for dust/water resistance during charging operations.

Durability under vibration and dynamic vehicle conditions

Electric vehicle connectors are put through their paces with around 2.5 million insertion cycles and spend 1,500 hours shaking under vibrations according to ISO 16750-3 standards. The contacts themselves are made with special beryllium copper alloys that keep resistance fluctuations below 5 milliohms even when subjected to 25G acceleration shocks. Think about what happens when someone drives over those nasty cobblestone streets at highway speeds - that's basically what these components experience in testing. Manufacturers also run thermal cycling tests from minus 40 degrees Celsius all the way up to plus 150 degrees to make sure materials stay stable throughout the expected 15 year lifespan of most EVs on the road today.

Case study: Thermal management in advanced NACS connectors during 350A discharge

A leading EV manufacturer's connectors demonstrate 58% faster heat dissipation than previous designs through:

- Silver-plated copper terminals with 95% IACS conductivity

- Integrated NTC thermistors monitoring ±1°C accuracy

- Aerogel-filled housings limiting surface temperatures to <65°C at 350A continuous load

This enables 10-minute 350 kW charging cycles without derating, maintaining 98.3% energy transfer efficiency per SAE J3271 benchmarks.

System Integration and Reliability of High-Voltage Connectors in EVs

High-voltage plugs form the critical pathways enabling energy transfer across EV subsystems. Their seamless integration determines both vehicle performance and operational safety, requiring precision engineering at every interface.

Integration of High-Voltage Connectors in Battery and Powertrain Systems

In modern electric vehicles, battery packs ranging from 400 volts to 800 volts connect to inverters, motors, and thermal systems via strong connectors that handle anywhere between 16 amps and 350 amps of current. The real challenge comes when these parts need to keep conducting electricity properly despite sudden temperature changes that can go all the way from minus 40 degrees Celsius up to 125 degrees Celsius. According to research published in Automotive Engineering last year, nearly nine out of ten problems with battery management systems actually start at the connectors themselves. That statistic really highlights just how critical these seemingly small components are for overall vehicle performance.

Role in Motor Drives, Onboard Chargers, and DC-DC Converters

High-voltage connectors serve three primary functions:

- Motor Drives: Deliver 250A, 350A bursts for acceleration while resisting electromagnetic interference

- Onboard Chargers: Facilitate AC-DC conversion at 240V, 500V with 95%+ efficiency

- DC-DC Converters: Step down voltages for auxiliary systems with <1% voltage drop

Impact of Connector Reliability on Overall EV Performance and Safety

According to data from SAE standards organization, connector problems cause around 74% of all high voltage system downtime in commercial electric vehicles. When connectors aren't mated properly within their tolerance range of plus or minus 1 Newton force, contact resistance jumps by about 35%. This increased resistance leads to faster thermal breakdown over time. Looking at recent safety research, engineers have found that better designed HVIL systems (those High Voltage Interlock Loops) cut down on dangerous arc faults during emergency disconnect situations by nearly two thirds. With next generation EVs pushing charging currents toward 350 amps, manufacturers are turning to innovative materials such as silver nickel contacts and PTFE insulation to keep these high power systems running reliably under extreme conditions.

Future Trends and Standardization Challenges in High-Voltage Plug Technology

Next-generation DC fast-charging standards supporting 350A and beyond

The electric vehicle market is really moving fast when it comes to charging tech these days. We're seeing next generation DC fast chargers aiming for current levels between 350A and 500A to work with those new 800 volt batteries. Some studies from automotive engineers show that going to 800 volts cuts down on conductor weight around 30 percent and lets vehicles charge at 350 kilowatts. What makes this important? Well, when cars charge super quick, there's less heat buildup in those high voltage connectors. This actually solves a big problem that's been holding back charge times from getting below 20 minutes. Manufacturers are excited about this because shorter charging means happier customers waiting less time at stations.

Ultra-fast charging networks and advanced connector materials

Emerging 800V charging stations demand connectors with 95 mm² cross-sectional copper conductors to safely manage 300A+ continuous loads. Manufacturers are adopting hybrid thermoplastic-elastomer composites for insulation, capable of withstanding sustained temperatures up to 150°C without compromising mechanical flexibility.

Aligning connector development with evolving battery technologies

With battery capacities exceeding 120 kWh in 2024 models, high-voltage plugs now require 1500V dielectric strength ratings to accommodate next-gen silicon-carbide inverters. This aligns with battery innovations like structural cell-to-pack architectures, where connectors double as structural load-bearing components in vehicle frames.

Global compatibility issues and the push for standardization (CCS vs. NACS)

The competing CCS and NACS plug standards create compatibility challenges, particularly in cross-continental EV logistics. Industry data reveals regional divides, CCS dominates 76% of European installations, while NACS claims 60% adoption in North America. This fragmentation hinders economies of scale, adding 15, 20% to connector manufacturing costs in dual-standard regions.

Frequently Asked Questions (FAQ)

What is the significance of high-voltage connectors in EVs?

High-voltage connectors in electric vehicles allow efficient power transfer between charging stations and vehicle batteries, supporting fast charging and enhanced vehicle performance.

How do different global charging plug standards vary?

Global DC fast-charging standards like CCS, CHAdeMO, GB/T, and NACS differ in voltage, current ratings, and regional adoption, impacting compatibility and charging efficiency.

What role does liquid cooling play in EV connectors?

Liquid cooling in high-current connectors is crucial for maintaining safe temperatures and preventing overheating, essential for consistent performance in fast charging scenarios.

How do advancements in charging technology benefit EV users?

Advancements such as higher voltage systems and improved connector designs allow for faster charging, increased driving range per charge, and enhanced safety features in EVs.

What are the challenges in achieving global standardization in EV plug technology?

Standardization challenges arise from differing regional standards like CCS and NACS, impacting compatibility, manufacturing costs, and cross-continental EV logistics.

Table of Contents

-

Understanding High-Voltage Plugs and Global EV Charging Standards

- The Role of High-Voltage Connectors in Electric Vehicles

- Comparative Analysis of Global DC Fast-Charging Plug Standards (CCS, CHAdeMO, GB/T, NACS)

- Voltage and Current Specifications Across Different Charging Standards

- From AC to DC: How High-Power EV Charging Infrastructure Supports Up to 350 kW and Beyond

- Electrical Performance of High-Voltage Plugs: Current, Power, and Efficiency

- Design and Safety Features of High-Voltage Connectors in EV Applications

- System Integration and Reliability of High-Voltage Connectors in EVs

- Future Trends and Standardization Challenges in High-Voltage Plug Technology

-

Frequently Asked Questions (FAQ)

- What is the significance of high-voltage connectors in EVs?

- How do different global charging plug standards vary?

- What role does liquid cooling play in EV connectors?

- How do advancements in charging technology benefit EV users?

- What are the challenges in achieving global standardization in EV plug technology?