The Critical Role of Low-Voltage Signal Plugs in EV Communication Networks

Understanding Low-Voltage Signal Plugs and Their Function in EVs

The low voltage signal plugs act kind of like the nervous system in electric vehicles, sending important data back and forth between all those sensors, controllers, and power components throughout the car. These connectors work within a 12 to 48 volt range which helps keep communication running smoothly without draining too much power. They're really important for things that need extra safety attention like managing the battery pack and detecting collisions. Take battery contactors for example. The low voltage signals actually control these high voltage parts inside EV batteries. When there's a problem or someone needs to do maintenance work, they isolate those dangerous electrical currents automatically. That's why mechanics always check them first when working on shop floor repairs.

How Physical Connector Integrity Enables Reliable Signal Transmission

Well built connectors keep data flowing smoothly even when faced with vibrations, extreme temperatures, and damp conditions that would mess up lesser designs. Manufacturers often incorporate things like heavy duty housing materials, IP67 plus protection against dust and water intrusion, plus those special locking mechanisms that resist shaking loose during operation. The thing is, one bad pin in these multi pin setups can really throw a wrench in CAN bus systems. We've seen it happen on factory floors where a tiny connection issue triggers all sorts of problems from annoying error messages flashing on dashboards to complete system failures in vehicle drivetrains. That's why most engineers put so much emphasis on getting the mechanical aspects right from day one.

Integration of Signal Pins in Key EV Connectors (CP, PP, CAN)

Modern EV charging and control systems rely on specialized low-voltage connectors:

- Control Pilot (CP): Manages charging current and session status via PWM signals

- Proximity Pilot (PP): Detects cable connection and vehicle readiness

- CAN Bus: Coordinates 500+ ECUs with data rates up to 1 Mbps

These interfaces ensure safe, synchronized interaction between the vehicle and charging infrastructure.

Data Flow from Sensors to Controllers: The Backbone of EV Intelligence

The average electric vehicle comes packed with around 200 different sensors, producing roughly 25 gigabytes worth of data every single hour. These low voltage connectors send all that live information straight to the domain controllers almost instantly something that matters a lot when it comes to things like predicting when parts might fail, keeping track of battery charge levels across individual cells, and adjusting power delivery as needed. For safety features to work properly, these systems need responses faster than 10 milliseconds flat out. And honestly? That kind of speed just isn't possible without those reliable, top quality electrical connections holding everything together.

Overcoming Signal Integrity Challenges in Harsh EV Environments

Key Factors Affecting Signal Integrity in Automotive Networks

Extreme temperatures ranging from -40 degrees Celsius all the way up to 125 degrees, along with high voltage electrical interference and constant mechanical shaking, really mess with signal quality in those low voltage signal connectors. The Society of Automotive Engineers has actually tracked this problem pretty closely, finding that contact oxidation alone accounts for around a quarter of all field failures, not to mention dielectric breakdowns which plague connectors handling analog sensor information. These problems hit CAN bus systems and battery management lines particularly hard. When voltages swing more than plus or minus 10%, it creates serious headaches for interpreting binary signals correctly, leading to all sorts of operational issues down the line.

Mitigating Electromagnetic Interference and Contact Resistance

Modern electric vehicles fight against interference using a three part shielding system that includes conductive elastomer gaskets, metalized plastic housings, and those twisted pair cables we all know about. These combined methods can cut down on electromagnetic interference by around 45 dB. The gold plated contacts are pretty impressive too. They keep their resistance under 5 milliohms even after being connected and disconnected thousands of times, which means the PLC systems and other control signals stay reliable throughout the vehicle's life. For DC fast charging ports specifically, manufacturers embed ferrite beads that do a great job at suppressing those pesky high frequency noises while still letting the 2 to 9 volt control signals go through without any problems.

Balancing Miniaturization with Signal Reliability in Connector Design

The number of connectors inside vehicles has gone up around 37% when we compare them to those old gas powered cars from 2019, but they still need to pass those tough ISO 16750-3 vibration tests. These tiny spring contacts spaced just 0.6mm apart actually save about 85% of the space that traditional blade connectors would take up. What's really interesting is how these special tin-silver mixtures stand up against corrosion problems in moving parts such as steering angle sensors. This means that lower voltage LIN networks can work alongside high voltage traction systems without any interference issues happening. And get this – even those little tire pressure monitoring systems mounted on wheels don't cause any problems with signal mixing.

Design and Material Innovations Enhancing Low-Voltage Signal Plug Performance

Advancements in Durability and Corrosion Resistance for Automotive Connectors

Today's low voltage signal plugs are made with top quality thermoplastic materials combined with nickel chromium alloys that can handle all sorts of harsh conditions including moisture, temperature changes, and contact with various chemicals. Testing in salt spray chambers reveals that the latest anti-corrosion coatings actually make these connectors last around 40% longer than what we used to see with older materials. The real world benefits? Reliable operation even when installed in tough spots like seaside locations or along highways where road crews spread salt during winter months to melt ice.

Gold-Plated Contacts and Precision Molding for Superior Connectivity

Coating connectors with gold at around 0.2 to 0.8 micrometers thick helps prevent oxidation problems and keeps electrical resistance down to less than 5 milliohms even after many connection cycles. When manufacturers use precision injection molding techniques, they can get parts within 0.05 mm tolerance range. This not only cuts down on insertion force by about 30%, but also gets rid of those tiny gaps between components that mess with signals. The result? Much better performance for things like CAN bus systems and various sensor connections. Just think what happens when there's a momentary interruption in these critical circuits it could bring entire systems to a halt.

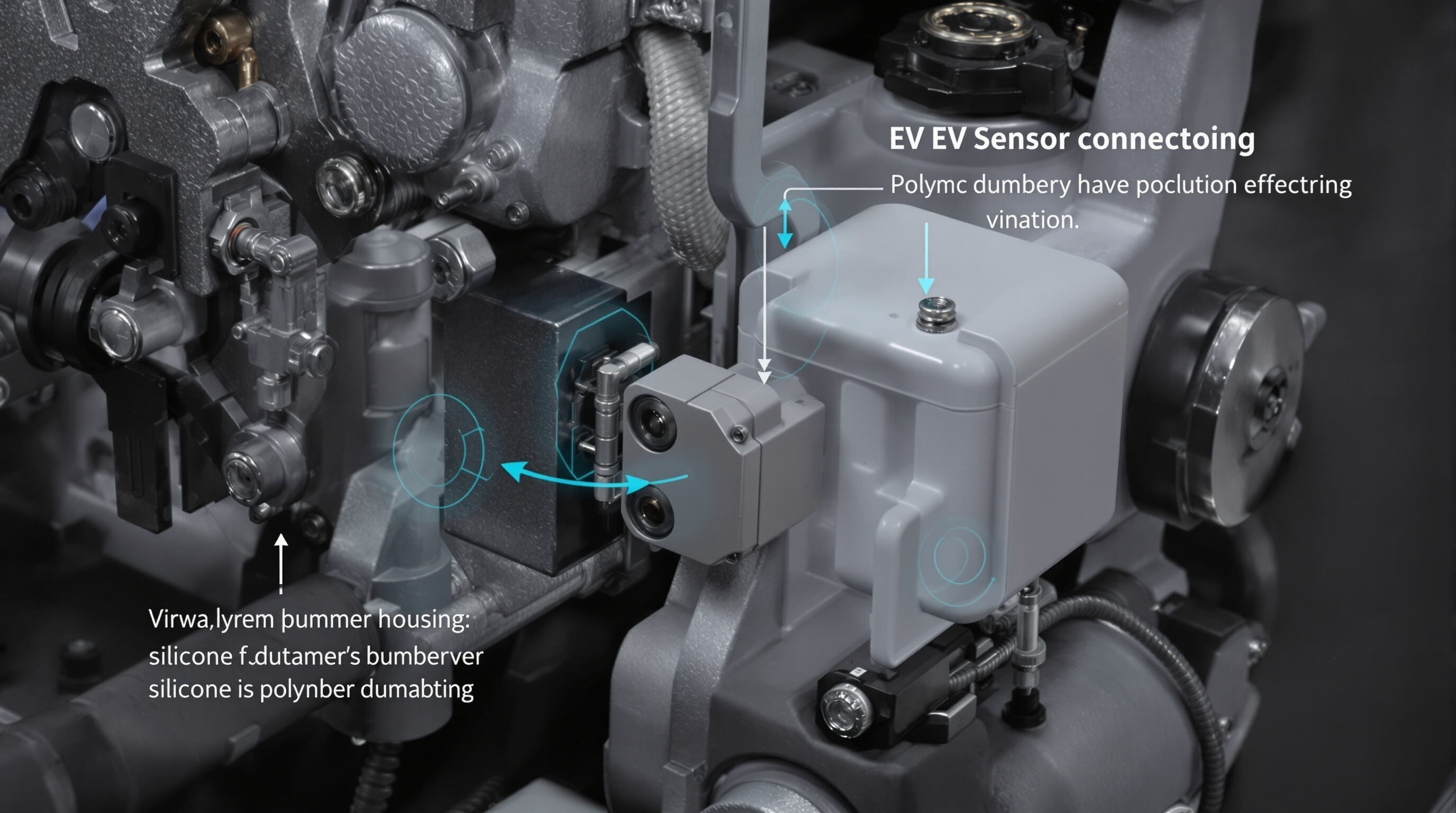

Thermal Stability and Vibration Resistance in Sensor and Control Unit Connectors

Polymer blends that can handle high temps stay dimensionally stable across a wide range, from as cold as -40 degrees Celsius all the way up to 150 degrees. This stability is really important for connectors positioned close to battery packs and motor assemblies where temperature fluctuations are common. The connectors also have vibration resistant designs with interlocking housings plus silicone dampeners built in. These components keep electrical contacts intact even when subjected to pretty intense vibrations at around 20G sinusoidal loads, which actually goes beyond what's required by the ISO 16750-3 standard. Without these design elements, we'd see problems with false readings coming from ADAS camera systems and issues with accurate voltage measurements in battery management systems, especially when vehicles go through rough road conditions or sudden maneuvers.

Standardization and Interoperability: Advancing Global EV Charging Compatibility

Global Standards for EV Connectors and Their Impact on Communication

Standards like CCS (Combined Charging System) and CHAdeMO have streamlined EV charging infrastructure by ensuring consistent power delivery and data exchange across manufacturers. A 2024 industry analysis found standardized communication protocols reduce signal interference by 42% compared to proprietary systems, directly improving battery management and safety monitoring accuracy.

Ensuring EV-Charger Compatibility Across Regions and Protocols

The whole issue of different voltages and communication standards across regions continues to be a headache for engineers working on global projects. Take China's GB/T standard versus Europe's CCS system - they actually have completely different pin layouts for those auxiliary signals, which creates compatibility problems when trying to deploy equipment internationally. Fortunately there are now modular connectors equipped with IP67 rated signal pins that can adapt to local specifications without messing up the data transmission. And let's not forget about multi protocol charging controllers either. These clever devices basically translate CAN signals using universal low voltage interfaces, so we're finally seeing some real progress in overcoming those pesky geographic barriers between markets.

Proprietary vs. Open Standards: Navigating the Industry Divide

While open standards like OCPP 2.0.1 (IEC 63584) dominate public charging networks, some automakers retain closed protocols for thermal management and fast-charging optimization. Recent data shows 78% of new DC fast chargers support dual-standard communication, accommodating both approaches without compromising signal stability in low-voltage control circuits—ensuring backward compatibility and future scalability.

FAQs

What role do low-voltage signal plugs play in electric vehicles?

Low-voltage signal plugs act as a communication conduit between various components in electric vehicles (EVs), ensuring seamless data flow and control over crucial systems like battery management and collision detection.

How do low-voltage connectors ensure reliable data transmission?

Low-voltage connectors maintain data transmission even in extreme conditions through robust design features including heavy-duty materials, IP67 protection, and locking mechanisms that resist vibrations.

Are there standard protocols for EV connectors globally?

Yes. Global standards like CCS and CHAdeMO ensure standardized communication and power delivery across manufacturers, facilitating compatibility in EV charging infrastructure.

How is connector miniaturization impacting EV design?

Connector miniaturization, such as using spring contacts spaced 0.6mm apart, saves space and allows for more components in EVs without compromising on data transmission or signal quality.

Table of Contents

- The Critical Role of Low-Voltage Signal Plugs in EV Communication Networks

- Overcoming Signal Integrity Challenges in Harsh EV Environments

-

Design and Material Innovations Enhancing Low-Voltage Signal Plug Performance

- Advancements in Durability and Corrosion Resistance for Automotive Connectors

- Gold-Plated Contacts and Precision Molding for Superior Connectivity

- Thermal Stability and Vibration Resistance in Sensor and Control Unit Connectors

- Standardization and Interoperability: Advancing Global EV Charging Compatibility

- Global Standards for EV Connectors and Their Impact on Communication

- Ensuring EV-Charger Compatibility Across Regions and Protocols

- Proprietary vs. Open Standards: Navigating the Industry Divide

- FAQs