The Role of OBC Harnesses in Modern Electric Vehicle Architecture

Defining OBC Harnesses and Their Function in On-Board Charging Systems

The OBC or On-Board Charger harness acts as the main connection point between an EV's charging port and battery pack. It handles the important task of converting AC power from outlets to DC that batteries can actually store, plus manages how much power gets sent where. Modern versions of these special wiring setups keep voltages stable and control heat buildup during charge sessions, often handling up to around 22 kilowatts of power. What makes them different from regular car wiring is their ability to deal with all that electrical noise generated by the power components inside. At the same time, they need to avoid interfering with other systems in the vehicle through proper electromagnetic shielding. This balance between performance and safety is what allows electric vehicles to charge efficiently without causing problems elsewhere in the car.

Integration of Battery and Charging Systems in EVs

Moving toward 800V battery setups in electric vehicles from 2024 onward means manufacturers had to completely rethink how they design those onboard charger harnesses. The higher voltage demands copper wires that are roughly 40% thicker than what was used in older 400V systems just to cut down on energy loss during operation. Plus there's all sorts of fancy shielding needed now to keep electromagnetic interference from messing with the sensitive battery management system components. Looking ahead, data coming out recently indicates that fully electric cars slated for 2025 will have around 2,000 more wiring points compared to traditional internal combustion engines. A good chunk of those extra connections comes specifically from these new OBC harness designs, making up about a quarter of the total increase in complexity across the board.

Impact of Battery Voltage and Capacity on OBC Harness Design

| Design Parameter | 400V System Requirements | 800V System Requirements |

|---|---|---|

| Conductor Cross-Section | 35 mm² | 50 mm² |

| Insulation Rating | 600V AC | 1000V AC |

| Thermal Load Tolerance | 105°C Continuous | 150°C Peak |

| Shielding Effectiveness | 60 dB | 80 dB |

Higher battery capacities (100+ kWh) directly influence OBC harness complexity, requiring real-time current monitoring through embedded sensors. For every 10 kWh increase in capacity, harness weight grows by 1.2 kg in typical 2024 EV configurations, driving adoption of aluminum-core cables and composite insulators to maintain power density targets.

Core Design Principles for High-Efficiency OBC Harness Integration

Power Requirements and Their Influence on OBC Harness Layout

Designing an OBC harness starts by matching conductor sizes and insulation characteristics to what each vehicle actually needs for power. Today's electric vehicles typically run on batteries between 400 volts and 800 volts according to the Department of Energy report from 2023. This means manufacturers generally need copper wires sized from 4 AWG all the way up to 2/0 AWG to manage those charging loads which range around 11 to 22 kilowatts. When cars use higher voltage systems, something interesting happens - the current drops about half, so we can actually space the wires closer together. But there's a catch here too. The insulation needs to be much stronger to stop any dangerous arcing issues. Take 800V systems as a good example. These require at least 1.5 mm thick insulation material in areas where lots of wiring is packed together tightly. It's all about finding that sweet spot between keeping things safe and saving valuable space inside the vehicle.

Balancing Efficiency, Power Density, and Component Size in OBC Design

How thermal factors influence the design of on-board chargers has become a major consideration in layout optimization these days. When manufacturers start using gallium nitride semiconductors, they can reach impressive efficiency levels around 96.5%, according to research from Oak Ridge National Laboratory back in 2022. These components work best when power densities go above 3.2 kW per liter. For space conscious applications, engineers are now favoring vertical arrangements where DC/DC converters sit right next to PFC stages. This approach cuts down on those pesky interconnections between components by about 40% compared to traditional flat layouts that take up so much room. Looking at ways to cut weight? Many companies are switching to aluminum bonded busbars which weigh only 0.89 kg per meter instead of the heavy copper alternatives at 2.7 kg per meter. Plus there's this new generation of printed circuit boards that handle temperatures up to 125 degrees Celsius continuously without breaking a sweat.

Critical Control Features: Fast PWM, High-Resolution ADCs, and Dead-Time Control

Precision control circuits mitigate losses in OBC harness systems:

- <100 ns dead-time compensation prevents shoot-through in totem-pole PFC stages

- 16-bit ADCs monitor bus voltages within ±0.5% tolerance

- 500 kHz PWM frequencies minimize inductor core losses

Microcontrollers like the TI C2000™ series integrate these features, enabling >98% effective energy transfer during 3-phase AC conversion (IEEE Transactions on Industrial Electronics 2023).

Thermal and Electrical Performance Optimization in Harness Routing

When it comes to harness routing, engineers use something called computational fluid dynamics or CFD for short to spot those pesky thermal hotspots before they become problems. This approach has been shown to drop temperatures by around 8 to 12 degrees Celsius when we implement things like segmented shielding and proper airflow channels throughout the system. Another key consideration is making sure high current lines don't run parallel to low voltage signal lines because that creates all sorts of electromagnetic interference issues. According to research from SAE International back in 2024, avoiding this parallel routing cuts down on these kinds of errors by nearly three quarters. And let's not forget about the cables themselves. The flexible ones with silicone jackets can handle over 20 thousand bending cycles right next to the chassis, which is pretty impressive considering they still need to withstand those brutal underhood temperatures of up to 150 degrees Celsius during normal operation.

System-Level Integration: Bridging PCB, Harness, and Vehicle Platform

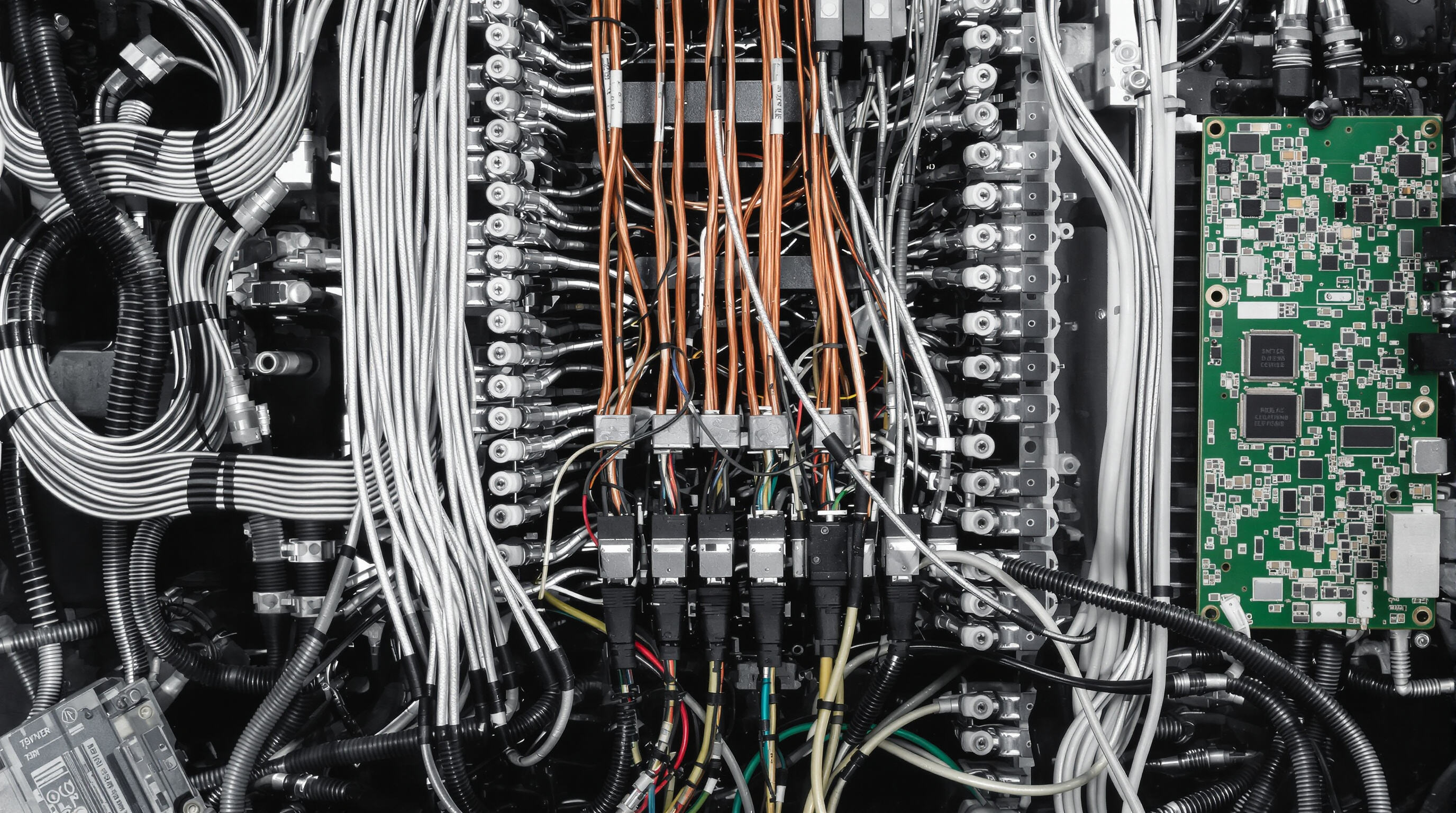

Overcoming Integration Challenges Between PCB and Wire Harness in OBC Systems

Electric vehicles today really need good coordination between their printed circuit boards (PCBs) and wire harnesses for the on-board charging (OBC) systems to work properly. According to some research published in EEWorld back in 2025, around seven out of ten integration problems come down to connectors not matching up or signals getting assigned wrong between the PCBs and harnesses. That's why many automotive engineers are turning to integrated software solutions these days. These platforms help keep everything aligned across different design teams when it comes to schematics, how connectors fit together, and where wires should go. Take EDA tools for instance they let designers check if PCBs and harnesses match up in real time. What this means is design projects that used to take weeks can now be done in just a few days, and there's far less chance of those annoying signal mismatches that everyone hates dealing with later on.

Harness Design for EVs With Advanced Electronic and Compact Architectures

The tight spaces inside electric vehicle frames mean that onboard charger harnesses have to strike just the right balance between being flexible enough to fit and still providing proper EMI shielding. Engineers are turning to 3D simulation software these days to figure out the best ways to bundle wires and position conduits near motor controllers and battery packs. There's also something called adaptive routing that helps keep things from getting in the way of those sensitive ADAS sensors. Luxury electric cars are pushing the envelope here too. Manufacturers are managing to build harnesses with bend radii under 10 millimeters now, which is pretty impressive when considering they still need to handle currents as high as 300 amps without any issues. This kind of engineering makes all the difference in creating sleek, high performance vehicles.

Addressing Tool Fragmentation and Interoperability in OEM Electrification Workflows

Car makers are really struggling these days trying to get their heads around all these separate CAD, ECAD, and MCAD systems when developing onboard computers. According to recent industry research from last year, engineering groups working with siloed tools end up spending almost twice as long verifying designs compared to those who have better integration. The smart companies out there have started adopting comprehensive software solutions that bring together mechanical engineers, electricians, and firmware specialists under one roof. These unified platforms cut down on prototype cycles dramatically too, with some firms reporting over two thirds fewer iterations thanks to built-in design validation features that catch problems early in the process.

Case Study: Integrated OBC Placement in a Front-Motor EV Platform

The latest front motor electric vehicle prototype managed to reach impressive space efficiency levels at around 92%. This was made possible by placing the onboard charger harnesses right next to both the power distribution unit and the motor inverter. The engineering team incorporated special thermal conduits that can handle about 150 watts worth of heat coming off nearby parts. They also designed service loops close to the firewall area so mechanics can replace harnesses within just 15 minutes total. This kind of quick access makes all the difference when companies need to maintain large fleets efficiently over time.

Optimizing Physical Placement and Serviceability of OBC Harnesses

On-board charger location considerations across vehicle platforms

Where the OBC harness is placed makes a big difference for how well the car charges and how balanced it feels when driving. Most front motor cars put their chargers close to where the battery sits because shorter cables mean fewer losses during charging. For rear drive models, manufacturers tend to stick the OBC system right next to other power electronics back by the rear wheels. Big names in electric vehicles really care about where these systems go since they want to avoid any electromagnetic interference problems. This matters a lot for things like the battery management system and those temperature control units that keep everything running smoothly without getting too hot.

Space-constrained integration in compact chassis and electric machinery

According to P3 Automotive's 2023 report, around two thirds of all new electric vehicle platforms are going with battery packs under 100 kWh. This means wiring harness designers face some serious challenges when it comes to space. They need to work within packaging constraints that are roughly 40% tighter than older designs allowed. The good news is there are some pretty impressive tools available now. Engineering teams can run simulations through advanced software packages that show exactly how different layouts affect both the weight of the harness and the size of those cable bundles. These analyses typically result in somewhere between 18 to 22 percent better utilization of space inside those cramped chassis compartments. And let's not forget about robotic assembly methods either. Modern systems can route cables with incredible accuracy, down to plus or minus 0.25 millimeters even in tricky spots such as door sills where fingers just won't reach or along the A-pillars that frame the windshield area.

Maximizing serviceability and accessibility in OBC harness routing

Good OBC design includes quick disconnects and standard connectors that cut down on maintenance time by around 30 to 45 minutes each time someone needs to service the equipment. When installing these systems, leaving extra cable length (about 150 to 200 mm) near panel access points makes replacing parts much easier without having to take apart the whole wiring harness. The sheathing material used also matters a lot since it needs to stand up to harsh conditions. Testing shows these corrosion resistant coatings last over 97% of the time after 10 years in salt spray environments according to SAE J2334 standards. This is especially important for OBC harnesses that get exposed to road grime and water regularly during operation.

Validation, Reliability, and Future Trends in OBC Harness Performance

Testing OBC Charging Systems Under Real-World Load and Thermal Cycles

The harnesses for onboard chargers go through pretty intense testing before they're approved for actual use in vehicles. We run them through temperature extremes from minus 40 degrees all the way up to plus 125, basically simulating what happens when cars sit in freezing garages or baking parking lots. Load tests also mimic what happens during regular driving conditions. These tests help spot where the insulation might break down or connectors could fail over time. According to research published by SAE last year, better heat management in these wiring systems can cut down on resistance problems by around 35% after about 100 thousand charging sessions. That's why most engineers working on this stuff are focusing their efforts on changing wire sizes and experimenting with different insulating materials. The goal is simple really - prevent those dangerous overheating situations that sometimes happen when people plug in their EVs too quickly.

Real-Time Validation and Simulation vs. Physical Prototyping Trade-Offs

Physical prototypes are still needed for checking EMI/EMC compliance, but most electric vehicle makers these days rely on real time digital twins to test wiring harnesses. According to Frost & Sullivan from last year, around two thirds of developers have adopted this approach. The simulation software saves companies about 220 thousand dollars per platform because it can spot voltage drops and electromagnetic issues long before anyone starts building actual hardware. Still there's a catch when dealing with high current situations above 22 kilowatts. These cases need what engineers call hybrid validation methods where they mix computer models with some real world testing components. It's not quite fully virtual yet for those power hungry applications.

Embedded Intelligence: Control, Diagnostics, and Adaptive Communication in OBC Microcontrollers

The latest onboard charger microcontrollers come equipped with built-in algorithms designed to check the condition of electrical harnesses using techniques such as impedance spectroscopy along with thermal gradient analysis. What makes these systems really valuable is their ability to predict when connectors might fail, often catching signs of wear about 800 charge cycles ahead of time. Many modern systems now incorporate adaptive communication protocols, including ones called CAN FD-XL, which let onboard chargers tweak their charging settings while they operate, responding to what's actually happening inside the battery at that moment. According to research published in IEEE Transactions on Power Electronics back in 2023, this kind of smart adjustment can cut down on wasted energy by around 12 percent, making the whole charging process much more efficient.

Future Trends in Smart Charging and Battery-Charger Compatibility Protocols

The new ISO 15118-20 standards are pushing the automotive industry toward wireless charging solutions. Manufacturers now need onboard charger (OBC) harness designs that maintain under 1.5% power loss even when there's a 15 cm gap between components. This requirement is forcing some pretty significant changes in how these systems are built. For instance, bidirectional charging technology means harnesses must manage those tricky 11 kW power flows going backward without causing voltage fluctuations that could damage sensitive electronics. Meanwhile, modular harness systems featuring those handy hot-swappable connectors are becoming increasingly popular among car makers. These allow for easier updates to charging hardware without having to completely tear apart and rebuild entire vehicles, which saves time and money during production cycles.

Frequently Asked Questions (FAQs)

What is the primary role of OBC harnesses in EVs?

OBC harnesses serve as the main connection between the electric vehicle's charging port and the battery pack, handling the conversion of AC power to DC and managing the power distribution efficiently.

Why are 800V systems significant in the design of OBC harnesses?

800V systems require thicker copper wires and advanced shielding to manage higher energy demands, improve efficiency, and reduce energy loss, influencing how modern EVs are designed.

How does higher battery capacity affect OBC harness design?

Higher battery capacities increase the harness complexity and weight, requiring innovations like aluminum-core cables and real-time current monitoring to maintain power density and efficiency.

What technological advancements are being integrated into OBC systems?

Technological advancements include the use of gallium nitride semiconductors, advanced insulation materials, and smart microcontrollers that enhance efficiency, thermal management, and adaptive communication.

Table of Contents

- The Role of OBC Harnesses in Modern Electric Vehicle Architecture

- Core Design Principles for High-Efficiency OBC Harness Integration

-

System-Level Integration: Bridging PCB, Harness, and Vehicle Platform

- Overcoming Integration Challenges Between PCB and Wire Harness in OBC Systems

- Harness Design for EVs With Advanced Electronic and Compact Architectures

- Addressing Tool Fragmentation and Interoperability in OEM Electrification Workflows

- Case Study: Integrated OBC Placement in a Front-Motor EV Platform

- Optimizing Physical Placement and Serviceability of OBC Harnesses

-

Validation, Reliability, and Future Trends in OBC Harness Performance

- Testing OBC Charging Systems Under Real-World Load and Thermal Cycles

- Real-Time Validation and Simulation vs. Physical Prototyping Trade-Offs

- Embedded Intelligence: Control, Diagnostics, and Adaptive Communication in OBC Microcontrollers

- Future Trends in Smart Charging and Battery-Charger Compatibility Protocols

- Frequently Asked Questions (FAQs)