Understanding the Discharge Gun and Its Role in Bidirectional Energy Flow

What Is a Discharge Gun and How Does It Enable Vehicle-to-Load (V2L) Functionality?

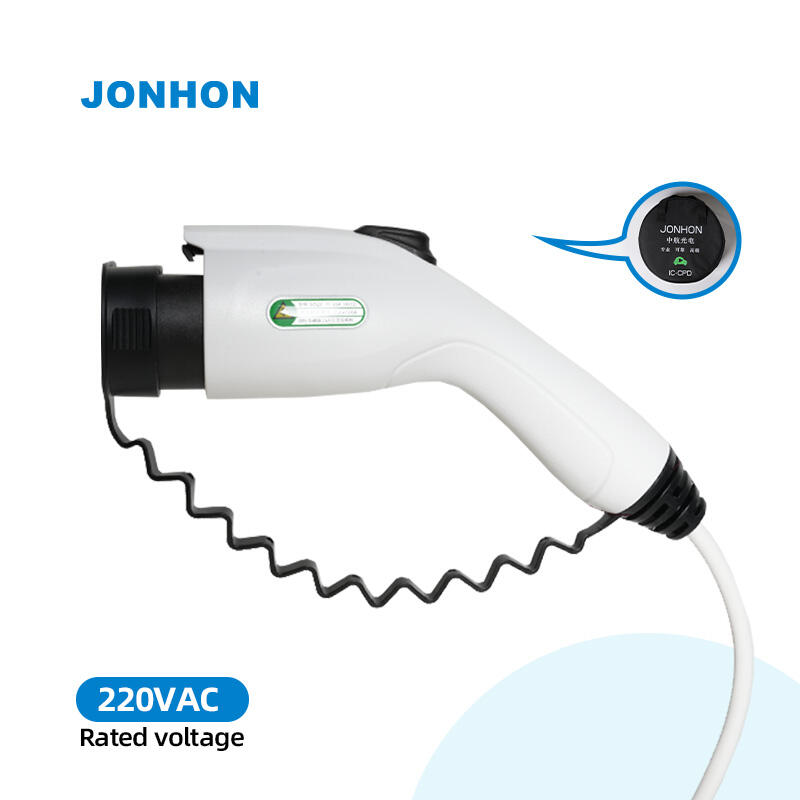

The discharge gun for electric vehicles lets owners send power back out from the car's battery to other devices using something called Vehicle-to-Load tech. What makes these different from regular charging cords is the smart electronics inside that figure out how much power to give and change the direct current from the battery into alternating current we can actually use. People have found all sorts of handy ways to put this to work, like running power tools at job sites or keeping lights on when there's a blackout at home. Some folks even hook up small refrigerators or medical equipment this way, basically transforming their cars into rolling generators whenever needed.

Integration of the Discharge Gun in Modern EV Energy Management Systems

Modern EVs integrate discharge gun functionality directly into their energy management systems, working in tandem with the battery management system (BMS) to:

- Automatically adjust output voltage (110V–240V) based on connected loads

- Detect ground faults in real time to enhance safety

- Maintain minimum charge thresholds to protect battery longevity

This coordination ensures reliable, safe power delivery without compromising vehicle performance or battery health.

Core Components: Power Intake Socket, Control Unit, and Internal Circuitry

Three key components enable the discharge gun's bidirectional operation:

| Component | Function | Safety Feature |

|---|---|---|

| Power Intake Socket | Connects securely to the EV's discharge port using IP67-rated connectors | Physical interlock prevents arcing |

| Control Unit | Communicates via CAN bus to manage load detection and power modulation | Complies with UL 2594 safety standards |

| Internal Circuitry | Converts DC to AC with over 95% efficiency using insulated-gate bipolar transistors | Dual-layer insulation prevents leakage |

Together, these elements support up to 3.6 kW of output while meeting IEC 62196-2 international safety requirements, making discharge guns essential for resilient, mobile energy solutions.

Advanced Safety Mechanisms in Discharge Gun Design

Mitigating Electrical Hazards During Discharge Operations

Discharge guns employ multilayer protections against arc flash and voltage spikes. Real-time monitoring analyzes current flow 800 times per second, while galvanic isolation separates high-voltage components from user-accessible surfaces. A 2023 study of industrial EVs found these features reduced electrical incidents by 67% compared to early-generation models.

Built-In Protections: Thermal Management, Overcurrent Cutoff, and Insulation Monitoring

Engineered safety systems include:

- Phase-change materials absorbing more than 450 J/g of thermal energy

- Solid-state relays that interrupt faults within 5 milliseconds

- Dielectric sensors detecting insulation wear at 0.1mm resolution

This layered approach maintains reliability even under sustained 10kW discharge conditions.

Real-World Impact: Case Study on Incident Prevention via Smart Circuitry

After implementing adaptive current-limiting algorithms, a major manufacturer observed significant improvements:

| Metric | Pre-Implementation | Post-Implementation |

|---|---|---|

| Overload Events | 23/month | 2/month |

| Emergency Shutdowns | 17/month | 0/month |

| Component Replacement | $9,200/month | $1,100/month |

Smart circuitry drastically reduced failures and maintenance costs, demonstrating the value of embedded intelligence.

Balancing Compact Design with Stringent Safety Standards

Despite compact designs—some under 150mm³—discharge guns meet ANSI B11.27-2020 safety benchmarks. Features like dual-redundant grounding paths and ceramic-composite insulators ensure robust protection without sacrificing portability or durability.

User-Centered Innovations Enhancing Discharge Gun Convenience

Intuitive Interfaces and One-Touch Activation for Seamless Operation

Modern discharge guns apply user-centered design to simplify V2L use. One-touch activation initiates power transfer in under five seconds, while backlit indicators and color-coded ports reduce errors in low-light settings. These improvements address 72% of usability issues reported in earlier models (EV Tech Journal, 2023).

Ergonomic and Portable Designs for On-the-Go Power Access

Manufacturers have reduced weight by 40% compared to first-generation units, enhancing portability. Textured grips improve handling safety by 31% in wet conditions, and IP67-rated casings ensure dependable outdoor performance—critical for emergency response and off-grid applications.

Smart Connectivity: Mobile App Integration for Remote Monitoring and Control

Many models now connect via Bluetooth 5.0 and Wi-Fi 6 to proprietary apps, enabling remote monitoring and control from up to 30 meters away. Users receive alerts for voltage anomalies or insulation faults, reducing thermal risks by 89% in field trials.

Expanding Applications: From Emergency Power to Commercial Use Cases

Home Backup Power Using the Discharge Gun During Grid Outages

When there's a blackout, discharge guns let electric vehicles power important stuff around the house like keeping food cold in fridges, turning on lights, and running necessary medical devices. A recent study from the National Renewable Energy Lab back in 2023 found that these two-way charging EVs can actually keep a home going for nearly 18 hours straight. That beats what most gas powered generators can do both in how long they last and how clean they are for the environment. What this means practically is that an electric car becomes sort of like a fancy portable battery worth about twelve thousand dollars sitting in someone's driveway. No need to install extra equipment or pay for complicated setups just to have backup power when needed.

Outdoor and Emergency Scenarios: Reliable Off-Grid Energy Supply

When people find themselves far from civilization whether it's during outdoor adventures or after natural disasters discharge guns provide around 3 to 7 kilowatts of mobile power needed for radios, lights, and critical support equipment. Many fire crews across California's dry areas have started using electric vehicles that can actually power water pumps and surveillance drones, which cuts down on diesel fuel usage by about forty percent according to recent reports from the state energy commission. These tough little power packs work just fine even when temperatures dip below zero degrees Fahrenheit or climb past 100 degrees, making them dependable tools no matter what kind of weather conditions they face.

EVs as Mobile Power Stations: Event Support and Job Site Applications

Commercial users leverage discharge guns to:

- Power food trucks and sound systems at events, reducing generator rental costs by 60%

- Run welding machines and compressors at construction sites

- Provide backup power for cell towers during natural disasters

These applications highlight the EV's evolving role as a scalable, mobile energy platform, though standardization remains a barrier for industrial uses exceeding 19.2 kW.

Future Trends and Industry Challenges in Discharge Gun Development

Material Innovation and Miniaturization in Discharge Gun Engineering

Advances in polymer composites and liquid-cooled circuit boards are driving smaller, lighter designs without sacrificing efficiency. Aerospace-grade aluminum alloys reduce casing weight by 35% versus steel, while ceramic-coated connectors improve heat dissipation by 20%. These innovations support growing demand for compact, stowable units that fit inside standard vehicle storage spaces.

Bridging the Gap: Demand Growth vs. Lack of Universal Standards

The global market for Vehicle to Load systems looks set to grow massively over the next few years, maybe even tripling by 2028 according to some estimates. But there's still a big problem with how different systems work together. A recent industry check found that around two thirds of all public charging spots can't actually handle those third party discharge devices because manufacturers use their own special communication protocols. Groups trying to sort this out are working on common standards for things like voltage levels and error messages, though there continues to be quite a gap between what regulations look like in North America versus Europe. This mismatch makes it hard to create truly universal solutions across different regions.

Collaborative R&D Efforts Driving Next-Gen Discharge Solutions

Partnerships between automakers and semiconductor companies are accelerating innovation. Modular discharge gun prototypes now offer adjustable outputs (1.8–11 kW) via swappable adapters. However, development continues toward fail-safe performance in extreme weather, with military-grade IP68 enclosures emerging as the new baseline for commercial deployments.

FAQ

What is a discharge gun used for?

A discharge gun enables electric vehicle owners to send power from the car's battery to other devices, transforming the vehicle into a portable generator.

How does the discharge gun improve safety?

The discharge gun incorporates features like real-time monitoring, galvanic isolation, and solid-state relays to ensure safety during power transfer operations.

Can discharge guns help during power outages?

Yes, discharge guns can power essential household devices during outages, making them a valuable backup power solution.

What challenges exist in discharge gun development?

Major challenges include the lack of universal standards and ensuring compatibility with existing charging infrastructure.

Table of Contents

- Understanding the Discharge Gun and Its Role in Bidirectional Energy Flow

- Advanced Safety Mechanisms in Discharge Gun Design

- User-Centered Innovations Enhancing Discharge Gun Convenience

- Expanding Applications: From Emergency Power to Commercial Use Cases

- Future Trends and Industry Challenges in Discharge Gun Development

- Material Innovation and Miniaturization in Discharge Gun Engineering

- Bridging the Gap: Demand Growth vs. Lack of Universal Standards

- Collaborative R&D Efforts Driving Next-Gen Discharge Solutions

- FAQ