Understanding High-Voltage EV Connectors and Their Role in Power Systems

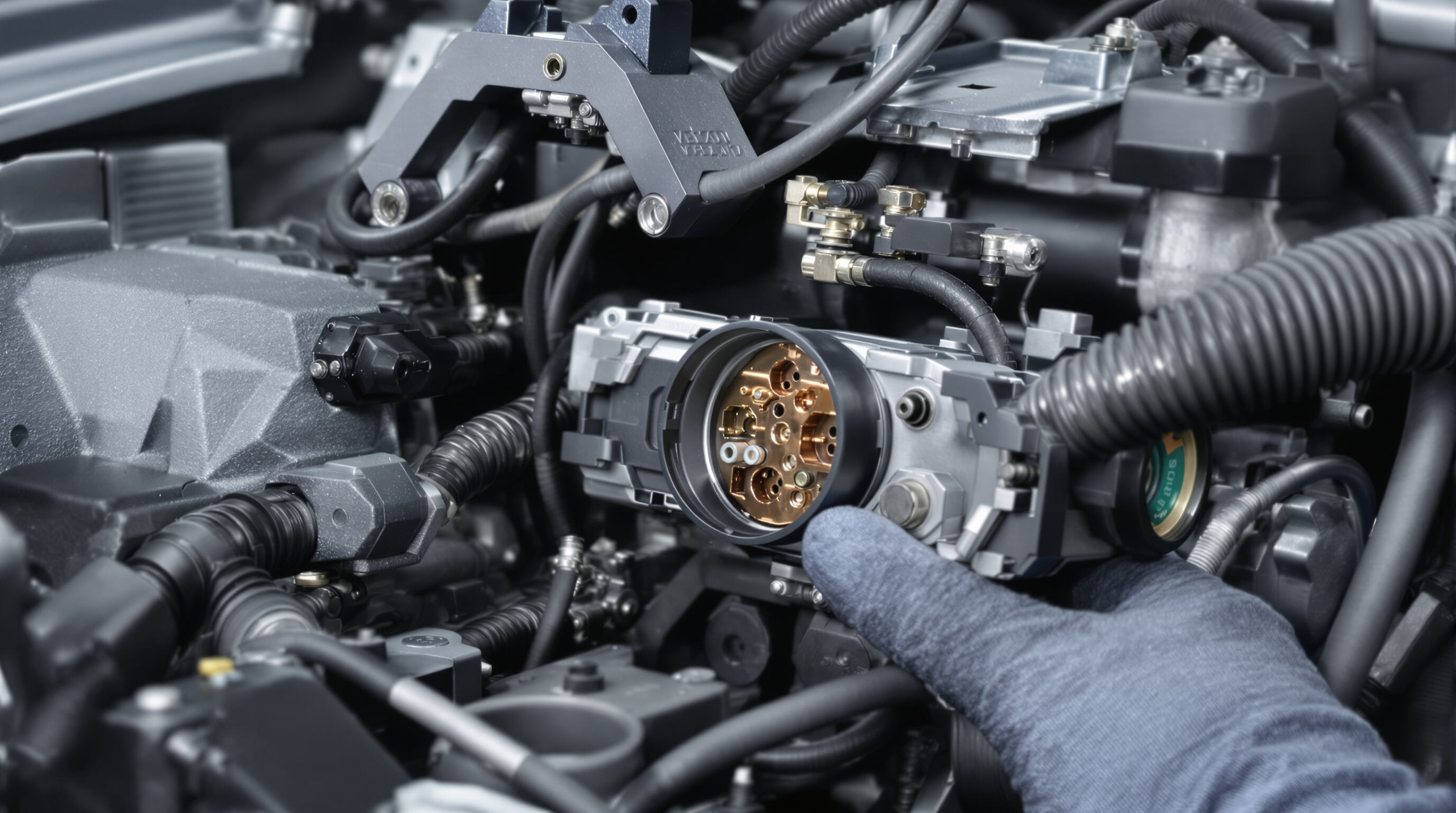

The connectors used in high voltage electric vehicles play a critical role in making sure power gets where it needs to go within those 300V to 800V systems found throughout modern EVs including battery packs, motor assemblies, and charging units. These aren't your standard car wires though. According to Globenewswire from 2025, they actually deal with current flows over 300 amps which means manufacturers need to use special materials and really careful engineering techniques just to keep energy losses down and prevent overheating issues. Looking at what's coming next in EV tech, we see designs for 800 volt systems already incorporating contact points with massive 95 square millimeter cross sections. This helps them stay cool under pressure while still conducting electricity effectively, something that becomes increasingly important as vehicles become more powerful.

Better designed connectors can cut down on voltage loss by around 15% when compared to older models, which means longer driving ranges and faster charging times for electric vehicles. Most manufacturers now build these connectors using materials that resist corrosion and add multiple layers of protection against electromagnetic interference. This helps keep all those powerful components talking to each other properly without signal issues. With electric cars moving towards more centralized wiring setups, having standard connectors makes sense because it allows for easier upgrades later on. Mechanics can swap out parts quickly for things like super fast charging stations or even systems that let energy flow back from the car to the grid during peak demand periods.

One big problem engineers face is finding the right balance between making things small enough while still letting heat escape properly. When connectors aren't built well, they can actually boost electrical resistance by around 40% when running continuously at temperatures near 120 degrees Celsius. Looking at industry numbers, about a third of all thermal problems in electric vehicles come down to either bad terminal crimps or insulation giving way somewhere. That's why getting manufacturing just right matters so much for these components. Fixing these kinds of issues means high voltage connectors become essential parts for distributing power reliably throughout today's electric car systems.

Essential Design Features for Performance and Protection

Terminals and Electrical Conductivity in High-Power EV Connectors

The connectors used for high power electric vehicles rely on precision terminals crafted from special copper alloys such as C19010 or C18150. These materials strike a good balance between great electrical performance, typically around 30 to 60 MS/m conductivity, while still being strong enough mechanically. What makes them stand out is their ability to keep contact resistance under 2 milliohms even when handling continuous currents exceeding 300 amps. To combat oxidation issues especially in damp environments, manufacturers often apply electrodeposited tin or silver coatings. This simple step goes a long way toward maintaining reliable conductivity despite challenging weather conditions that would otherwise degrade performance over time.

| Material | Conductivity (MS/m) | Tensile Strength (MPa) | Use Case |

|---|---|---|---|

| Pure Copper | 58 | 210 | Low-vibration battery links |

| C18150 Chromium Copper | 46 | 480 | High-stress charge ports |

| Aluminum 6061 | 35 | 290 | Lightweight cable lugs |

EMI Shielding for Signal Integrity and System Stability

Around 78% of electric vehicle electrical problems actually come down to electromagnetic interference according to SAE International's 2022 report. Fighting against EMI requires what's called multi layer shielding technology. This typically involves combining copper braids coated with nickel that need at least about 85% coverage area along with those special ferrite cores. These materials work together to cut down on unwanted noise signals somewhere between 40 to 60 decibels when looking at frequency ranges from roughly 10 million hertz all the way up to 1 billion hertz. For connectors themselves, manufacturers often go for housing made from either metallized plastics or incorporate conductive gaskets into their design. What happens then is something engineers call the Faraday cage effect where these components basically act as barriers protecting important parts like CAN bus networks and power circuits from getting disrupted by nearby electrical signals.

Sealing and Ingress Protection (IP67, IP6K9K) for Harsh Environments

EV connectors endure extreme environmental conditions — including road spray, dust, and temperatures from -40°C to 150°C — through triple-sealing strategies:

- Primary Seal: Silicone overmolding bonds housing to cable, validated through 1,500 thermal cycles

- Secondary Seal: Extruded EPDM gaskets with <15% compression set ensure IP6K9K compliance, resisting 100-bar water jets at 80°C

- Tertiary Seal: PTFE-coated terminal interfaces block capillary water ingress

IP67-rated connectors prevent entry of 99.9% of 75 μm particles, while IP6K9K variants withstand high-pressure washdowns — critical for underbody-mounted charging ports.

Safety, Reliability, and Mechanical Assurance in Connector Systems

High-Voltage Interlock Loop (HVIL) and System Safety Protocols

EV connectors integrate high-voltage interlock loop (HVIL) systems that monitor connection integrity in real time, cutting power within sub-100ms if disengagement is detected. This fail-safe mechanism prevents accidental exposure to live terminals and aligns with global EV safety standards mandating rapid fault response.

Preventing Electrical Arcing and Ensuring Fail-Safe Disconnection

Dual-stage locking mechanisms and gas-tight terminal designs mitigate arcing risks in 800V+ systems. Silver-nickel plating sustains stable conductivity over 50,000 mating cycles, while angled insertion paths eliminate partial engagement — one of the leading causes of insulation failure.

Connector Position Assurance (CPA) and Robust Locking Mechanisms

CPA systems provide tactile feedback and vibration-resistant secondary locks, capable of withstanding 15G mechanical shocks without disconnection. Overmolded stainless-steel latches exceed automotive durability requirements, ensuring uninterrupted power delivery in battery and drivetrain applications.

Terminal Crimping Quality and Long-Term Connection Reliability

Automated crimping processes achieve less than 5% compression variance, eliminating microgaps that lead to fretting corrosion. Gold-plated terminals paired with hydrophobic seals significantly reduce moisture-related degradation, a factor in 18% of field failures according to 2023 electrification studies.

Durability Under Extreme Conditions: Temperature, Vibration, and Stress

Thermal Management and Operating Temperature Ranges

High-voltage EV connectors operate reliably from -40°C to 125°C, meeting Mil-STD-810H 2023 thermal specifications. Advanced designs employ high-temperature thermoplastics like polyphenylene sulfide (PPS) and integrated cooling interfaces to dissipate heat from batteries and power electronics. Effective thermal management prevents resistance spikes that compromise efficiency in extreme climates.

Vibration Resistance and Mechanical Durability in Dynamic Environments

Connectors must endure road-induced vibrations exceeding 30G RMS. Anti-resonant features — such as silicone-rubber dampening pads and strain-relief boots — combined with IP6K9K-sealed housings, prevent fretting corrosion and maintain contact resistance below 1 mΩ after 5,000+ hours of simulated off-road testing. These enhancements ensure consistent power delivery despite constant mechanical stress.

Locking Mechanisms Designed for Continuous Operational Stress

Secondary locking systems (CPA) with stainless-steel latches sustain 50N retention force through 500+ mating cycles. Overmolded connectors using glass-fiber-reinforced shells resist torsional deformation, crucial for DC fast-charging ports subjected to frequent plugging. This robustness prevents accidental disconnects under 800V/500A loads, satisfying ISO 20653 vibration-resistance benchmarks.

Applications and Future Trends in High-Voltage EV Connector Technology

Integration Across Battery Packs, Charging Systems, and Power Electronics

High voltage connectors basically act as the connection points between batteries, charge ports, and all those electronic parts that make electric cars work. Looking at market trends, the business around these connectors should see some serious growth too. We're talking about a jump from around $1.7 billion back in 2022 to nearly $3.5 billion by 2029 as more people switch to electric vehicles. Car manufacturers are already pushing forward with newer tech platforms that handle 800 volt systems, and there are even prototypes coming out in 2025 that can manage components rated at 1,000 volts. What this means for real world applications is that different parts of the car's electrical system can talk to each other much better, which helps meet the ever increasing need for faster charging and overall vehicle performance improvements.

Power Requirements by Component: Onboard Chargers, DC/DC Converters, and More

Onboard chargers require connectors rated for 7–22 kW AC charging, whereas DC fast-charging systems need components capable of handling 150–350 kW. DC/DC converters rely on connectors that maintain stability under fluctuating loads up to 300 amps, ensuring reliable voltage regulation across the vehicle’s electrical architecture.

Case Study: High-Power Connector Implementation in a Leading EV Platform

A 2024 industry analysis revealed that 28% of new EV models feature 800V-ready connectors (Future Market Insights, 2024). One manufacturer achieved a 15% reduction in charging time through optimized connector design, demonstrating improved thermal management and a 20% increase in power density over prior generations.

Next-Gen Trends: Miniaturization, Higher Power Density, and Smart Charging Integration

Emerging designs focus on miniaturization without sacrificing current capacity — prototypes show a 30% size reduction compared to 2023 models. Integrated smart sensors enable real-time monitoring of temperature and connection integrity, paving the way for predictive maintenance and enhanced system diagnostics in next-generation EVs.

Frequently Asked Questions

-

What is the role of high-voltage connectors in electric vehicles?

High-voltage connectors are crucial for distributing power efficiently across the EV's systems, including battery packs and motor assemblies. They manage significant current flows while minimizing energy losses and preventing overheating.

-

Why is EMI shielding important in EV connectors?

EMI shielding is vital to protect the vehicle's electronic systems from electromagnetic interference, ensuring smooth communication between components without signal disruption.

-

What are some key materials used in high-power EV connectors?

Common materials include special copper alloys like C19010 and C18150 due to their balance between electrical conductivity and mechanical strength, along with advanced coatings to prevent oxidation.

-

How do EV connectors manage harsh environmental conditions?

EV connectors use triple-sealing strategies and durable materials to resist road spray, dust, and extreme temperatures, maintaining functionality in challenging environments.

-

What future trends are emerging in high-voltage EV connector technology?

Trends include miniaturization without capacity loss, higher power density, and smart charging integration for real-time monitoring and predictive maintenance.

Table of Contents

- Understanding High-Voltage EV Connectors and Their Role in Power Systems

- Essential Design Features for Performance and Protection

- Safety, Reliability, and Mechanical Assurance in Connector Systems

- Durability Under Extreme Conditions: Temperature, Vibration, and Stress

-

Applications and Future Trends in High-Voltage EV Connector Technology

- Integration Across Battery Packs, Charging Systems, and Power Electronics

- Power Requirements by Component: Onboard Chargers, DC/DC Converters, and More

- Case Study: High-Power Connector Implementation in a Leading EV Platform

- Next-Gen Trends: Miniaturization, Higher Power Density, and Smart Charging Integration

- Frequently Asked Questions